Projects

Reym B.V. / Tronox Filter Press Elements Cleaning Machine

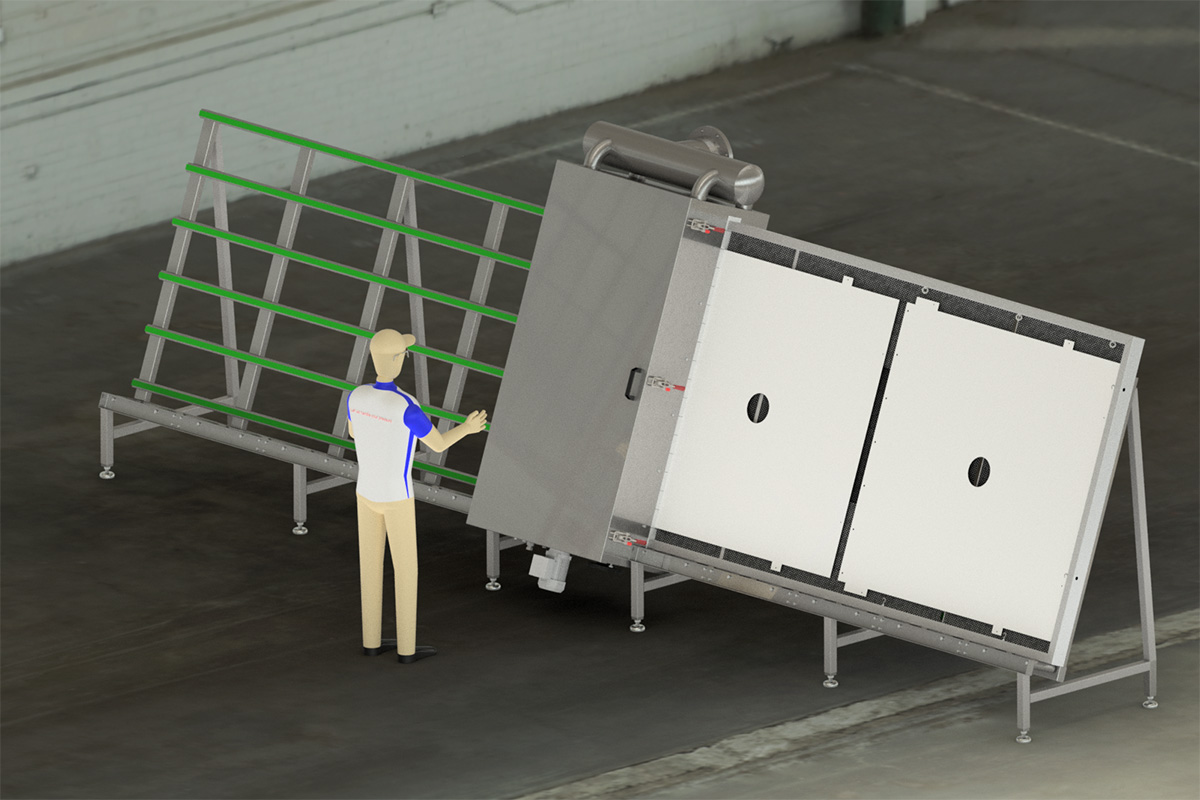

Reym B.V. and Tronox partnered with Derc Salotech to design, manufacture, and install an automated cleaning machine for cleaning contaminated filter elements in a filter press using high-pressure water jets.

Engineering, Production, and Installation

This turnkey project involved collaboration between Derc Salotech and the customer, Reym B.V. / Tronox, for initial engineering. Derc Salotech was responsible for in-house production and on-site installation and commissioning at the Tronox factory.

The cleaning machine is designed to automate the cleaning process of the filter elements using high-pressure water without any emissions. All wastewater generated during the cleaning process is collected for proper disposal. The machine is constructed using stainless steel, ensuring durability and resistance to corrosion. It is equipped with a control panel and integrated with a high-pressure pump, which includes emergency stop (E-stop) and start-stop functionalities.

The cleaning process operates at a working pressure of 500 Bar, delivering a flow rate of 130 liters per minute. The flow is distributed across 8 oscillating manifolds, each equipped with fan-jets to achieve a thorough cleaning result. The machine’s production capacity allows for cleaning up to 45 filter elements per day. Once cleaned, the filter elements can be disposed of as standard waste.

Overall, the automated cleaning machine provided by Derc Salotech facilitates efficient and effective cleaning of filter elements, contributing to improved performance and longevity of the filter press system at Reym B.V. / Tronox.

More info about this project?

Get in touch with our support team

+31 186 - 62 14 84