DERC Salotech

At what pressure does water cut steel?

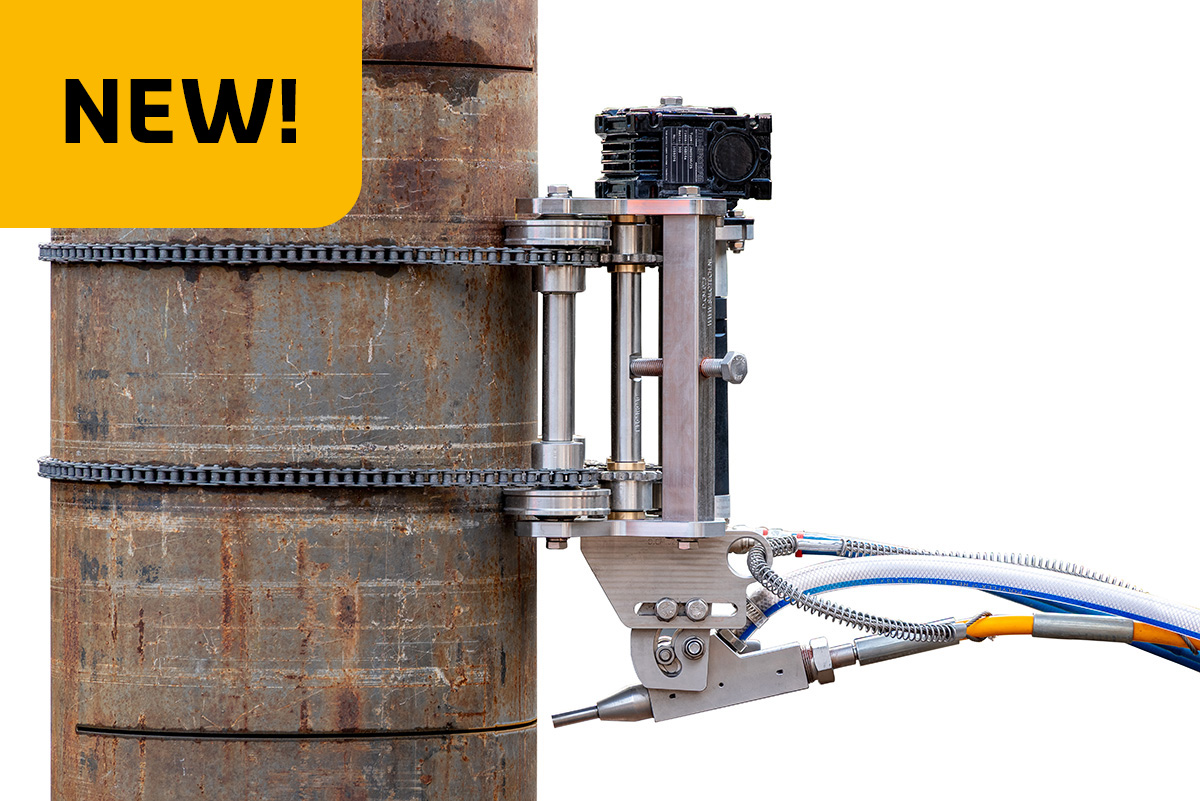

DERC Flexa-Jet Chain Manipulator

The DERC Chain Manipulator is an advanced tool designed for cutting pipes with a minimum diameter of 168 mm.

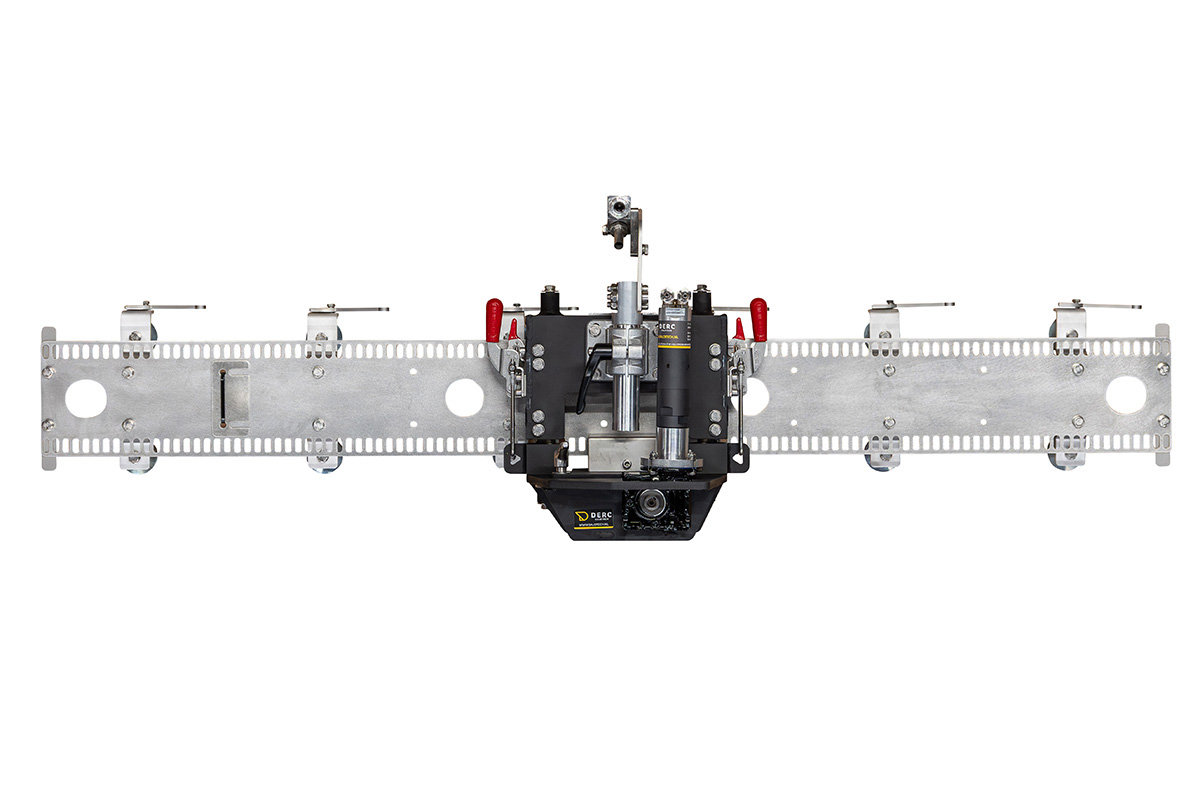

DiscoverDERC Flexa-Jet Abrasive Cutting System

Versatile system for industrial cold cutting applications using ultra-high pressure water.

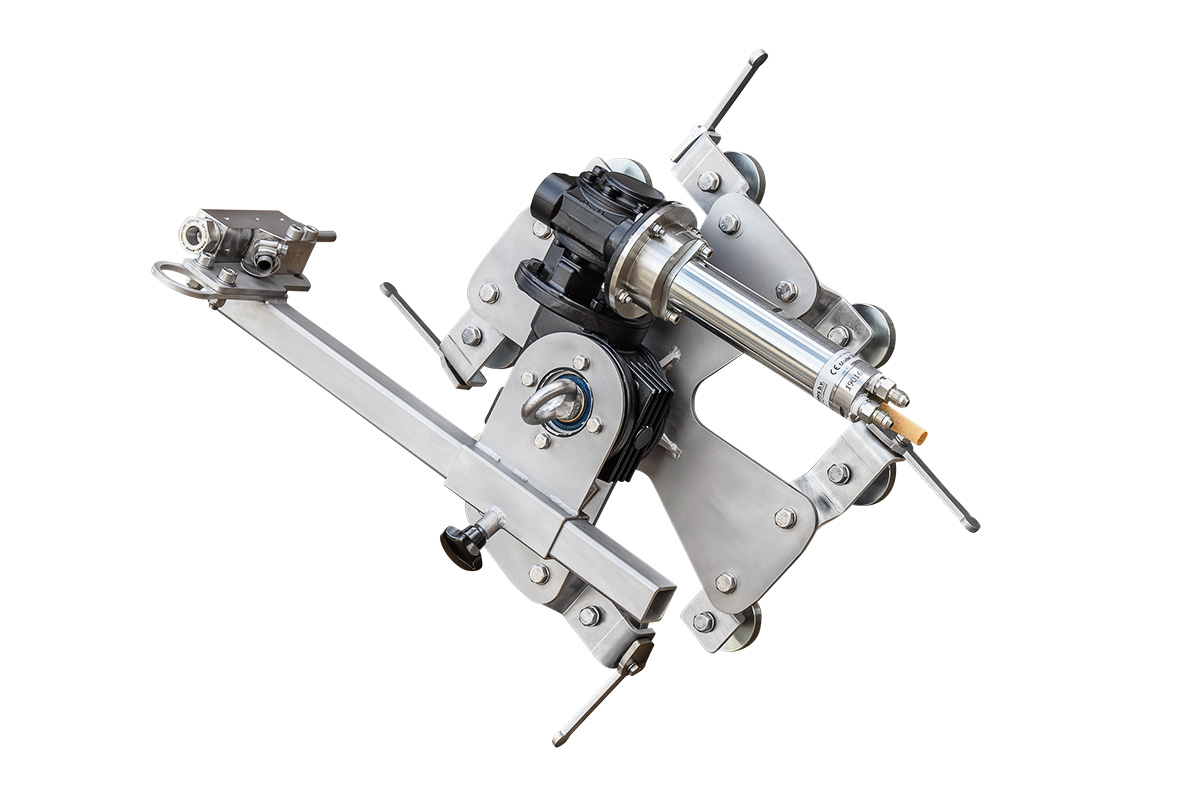

DiscoverDERC Small Radius Cutter

Radius Cutter for cold cutting of circular holes of ᴓ50-450 mm in various materials.

DiscoverWater needs extremely high pressure to cut through steel, typically ranging from 30,000 to 90,000 PSI (2,068 to 6,205 BAR) (pounds per square inch). However, water pressure alone isn’t enough for effective steel cutting. Most industrial applications combine high-pressure water with abrasive materials like garnet to achieve clean, precise cuts. The exact pressure you’ll need depends on several factors including steel thickness, grade, and your desired cutting speed.

Understanding water pressure requirements for cutting steel

When you’re working with steel cutting applications, understanding pressure requirements is fundamental to achieving successful results. Water typically needs pressures between 30,000 to 90,000 PSI (2,068 to 6,205 BAR) to cut steel effectively, but this range varies significantly based on your specific application.

Pure water alone rarely cuts steel efficiently. That’s why industrial operations almost always add abrasive materials to the water stream. These abrasives, usually garnet particles, dramatically enhance the cutting capability by creating a more aggressive erosion process at the cut surface.

The relationship between pressure and cutting effectiveness isn’t linear. Thicker steel requires higher pressures, harder steel grades demand more pressure than mild steel, and if you need faster cutting speeds, you’ll need to increase the pressure accordingly. For instance, cutting 1-inch (2.54 cm) mild steel might work well at 60,000 PSI (4,137 BAR) with abrasives, while 3-inch (7.62 cm) hardened steel could require the full 90,000 PSI (6,205 BAR) for efficient cutting.

How does high-pressure water actually cut through steel?

The physics behind waterjet cutting involves accelerating water through an incredibly small orifice, typically 0.003 to 0.020 inches (0.076 to 1.2 mm) in diameter. This acceleration creates a high-velocity stream that can reach speeds up to three times the speed of sound. At these velocities, water becomes a powerful cutting tool through kinetic energy transfer.

When abrasive particles mix with this high-speed water stream, they act like tiny cutting tools. The water accelerates these particles, and upon impact with the steel surface, they create micro-fractures. This process, called erosion cutting, removes material particle by particle rather than melting or burning through like traditional cutting methods.

The cutting mechanism works through continuous impact and material removal. Each abrasive particle strikes the steel surface, creating tiny cracks and removing microscopic amounts of material. Millions of these impacts per second gradually erode a path through the steel, creating a narrow kerf (cut width) typically ranging from 0.020 to 0.050 inches (0.508 to 3 mm).

What factors determine the required cutting pressure?

Several variables affect the pressure requirements for your steel cutting operations. Understanding these factors helps you optimise your cutting parameters for efficiency and quality.

Steel thickness stands as the primary factor. Here’s how pressure typically scales with thickness:

- 0.25-inch (6.35 mm) steel: 30,000-45,000 PSI (2,068-3,103 BAR) with abrasives

- 1-inch (2.54 cm) steel: 36,000-60,000 PSI (2,500-4,137 BAR) with abrasives

- 2-inch (5.08 cm) steel: 36,000-75,000 PSI (2,500-5,171 BAR) with abrasives

- 3-inch+ (7.62 cm+) steel: 36,000-90,000 PSI (2,500-6,205 BAR) with abrasives

Steel grade and hardness significantly influence pressure needs. Mild steel cuts easier than stainless steel or hardened tool steel. The material’s tensile strength and hardness directly correlate with required cutting pressure, sometimes demanding 20-30% more pressure for hardened steels compared to mild steel of the same thickness.

Your cutting speed requirements and precision needs also play important roles. Faster cutting speeds require higher pressures, while precision cuts might actually benefit from slightly lower pressures with slower feed rates to minimise taper and improve edge quality.

What’s the difference between pure waterjet and abrasive waterjet cutting?

Pure waterjet systems typically operate at 30,000-60,000 PSI (2,068-4,137 BAR) and work well for soft materials like foam, rubber, or thin plastics. However, they’re rarely suitable for steel cutting. The water stream alone lacks the cutting power to efficiently erode steel surfaces, making the process impractically slow or impossible for most steel applications.

Abrasive waterjet systems, also known as cold cutting, operate at higher pressures, typically 36,000-90,000 PSI (2,500-6,205 BAR), and mix abrasive particles with the water stream. This combination dramatically increases cutting capability, making it the standard choice for steel and other hard materials. The abrasive particles do the actual cutting work, while the high pressure water jetting accelerates and directs them.

The addition of abrasives transforms the cutting process entirely. Where pure water might struggle to mark steel surfaces, abrasive waterjets can cut through several inches of hardened steel. This capability comes from the abrasive particles’ ability to create the micro-fracturing necessary for material removal, something pure water cannot achieve effectively on hard materials.

How do you choose the right pressure for your steel cutting application?

Selecting the appropriate pressure for your specific needs involves balancing multiple considerations. Start by evaluating your production volume requirements. High-volume operations often benefit from maximum pressure to achieve faster cutting speeds, while lower-volume work might prioritise precision over speed.

Edge quality requirements significantly influence pressure selection. Higher pressures generally produce faster cuts but can increase taper and reduce edge smoothness. If you need superior edge quality for precision parts, consider using moderate pressures with optimised feed rates.

Operating costs factor into pressure decisions too. Higher pressures consume more energy and cause faster wear on pump components and cutting heads. Calculate the trade-off between increased productivity and higher operating costs to find your optimal pressure range.

Safety protocols become increasingly important at higher pressures. Ensure your team has proper training and your facility meets all safety requirements for high pressure water jetting operations. Equipment manufacturers can provide specific guidance on test cutting procedures to help you optimise parameters for your unique applications.

Key takeaways for high-pressure steel cutting applications

Steel cutting with waterjet technology requires pressures typically ranging from 30,000 to 90,000 PSI (2,068 to 6,205 BAR), with most applications falling in the 36,000-90,000 PSI (2,500-6,205 BAR) range when using abrasives. The addition of abrasive materials is practically mandatory for steel cutting, transforming water from a cleaning tool into a powerful cutting instrument.

Multiple factors affect your pressure selection, including steel thickness, grade, desired cutting speed, and edge quality requirements. Understanding these variables helps you optimise your cutting operations for both efficiency and quality.

At DERC Salotech, we understand the complexities of high-pressure water jetting applications in industrial settings. Our expertise spans decades of developing solutions for demanding environments where precision and reliability matter most. Whether you’re cutting steel, cleaning industrial surfaces, or preparing materials for further processing, having the right equipment configured for your specific needs makes all the difference. Visit our product page to explore professional equipment options designed for your industrial applications.

Questions?

Get in touch with our support team

+31 186 - 62 14 84