DERC Salotech

What are the risks of high pressure water jetting?

TST Sweden AB Workplace Safety Solutions

TST offers a complete assortment of workspace safety solutions of the highest standard.

DiscoverTST Sweden AB Protective Clothing

TST offers a complete assortment of personnel protection equipment of the highest standard.

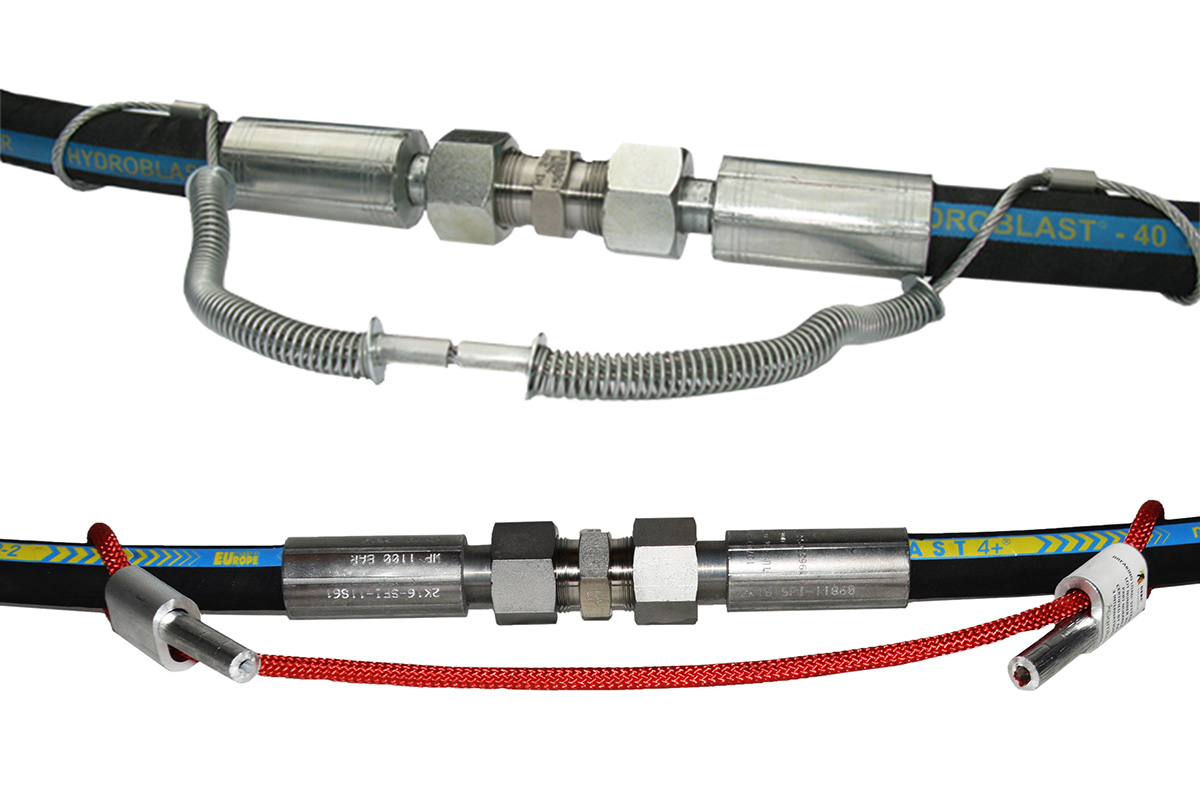

DiscoverDERC Hose Whip Checks

Hose Whip Checks are required as safety measure to avoid injury in case of hose or coupling failure.

DiscoverDERC Hose Catcher VE.21000-22000

Adjustable accessory tool for the safe high pressure cleaning of pipes in small places.

DiscoverHigh pressure water jetting carries significant risks including severe injection injuries, equipment failures and environmental hazards. The extreme pressures involved can cause deep tissue damage, cuts and impact trauma. Equipment malfunctions such as hose ruptures or pump failures can create sudden pressure releases that endanger operators. Environmental factors like slippery surfaces, flying debris and noise exposure increase the risks even more. Because of this, proper training and working according to recognized guidelines is essential.

Training and recognised guidelines

We strongly advise following the training and safety guidelines from:

These organisations prescribe or require certified training, safe working methods, PPE standards, inspection routines and emergency procedures. Following these guidelines helps you work safely and professionally. For highquality training, we recommend contacting DERC Adviesgroep in Stellendam. They provide recognised SIR and WJA training programmes and can also deliver customised onsite training worldwide.Understanding high pressure water jetting risks

High pressure water jetting operations present multiple safety challenges. The combination of extreme pressures, powerful equipment and industrial environments creates a highrisk situation. Pressures ranging from 1,000 PSI (69 BAR) up to 40,000 PSI (2,758 BAR) can cause devastating injuries in milliseconds. Even a small leak or misdirected spray becomes a serious threat at these levels.

What are the most serious injury risks from high pressure water jets?

Injection injuries are the most severe threat. A small puncture wound can hide extensive internal damage. Other key risks include:

- lacerations caused by cutting action of the water jet

- impact trauma when operators are thrown off balance

- eye and face injuries from direct or indirect spray

How can equipment failure create dangerous situations during water jetting?

Equipment complexity adds another layer of risk. When one component fails, the entire operation becomes dangerous. Examples include:

- hose failures that cause violent hose whip

- pump malfunctions causing sudden pressure spikes or drops

- nozzle blockages that create dangerous backpressure

- connection failures at fittings or couplings

- control system malfunctions that prevent quick shutdown

What environmental hazards should operators watch for?

High pressure water jetting also creates environmental hazards such as:

- slippery working surfaces

- flying debris like rust, paint or concrete

- noise levels that require hearing protection

- contaminated spray containing chemicals, dust or biological hazards

- confined space dangers with poor ventilation

- electrical hazards when water reaches power sources

How do you prevent high pressure water jetting accidents?

Safe operation requires training, preparation and discipline. Key steps include:

- completing certified training (WJTA, WJA, SIR, EWJI, DIRV)

- wearing PPE designed for high pressure applications

- performing preoperation equipment checks

- establishing clear safety zones

- never pointing jets at people

- using lockout/tagout during maintenance

- preparing emergency response plans and keeping first aid available

Why choosing reliable equipment matters for safety

Quality equipment reduces your exposure to hazards. Professional systems include safety features like automatic pressure relief, emergency shutdown systems and robust hose assemblies. Regular maintenance programmes ensure that equipment remains safe and reliable. Investing in dependable equipment protects your people and ensures efficient operations across all industrial applications.

DERC Products and safety

We understand the importance of safety in high pressure water jetting operations. Our equipment incorporates advanced safety features and undergoes extensive testing to ensure reliable performance in demanding industrial environments. You can explore our range of safety-focused water jetting solutions designed specifically for technical professionals who prioritise both performance and protection.

Investing in reliable equipment isn’t just about avoiding accidents, it’s about maintaining consistent operations whilst protecting your most valuable asset – your people. Quality systems provide the dependability you need for safe, efficient water jetting operations across all industrial applications.

Questions?

Get in touch with our support team

+31 186 - 62 14 84