DERC Salotech

What is the risk assessment for high pressure water jetting?

TST Sweden AB Workplace Safety Solutions

TST offers a complete assortment of workspace safety solutions of the highest standard.

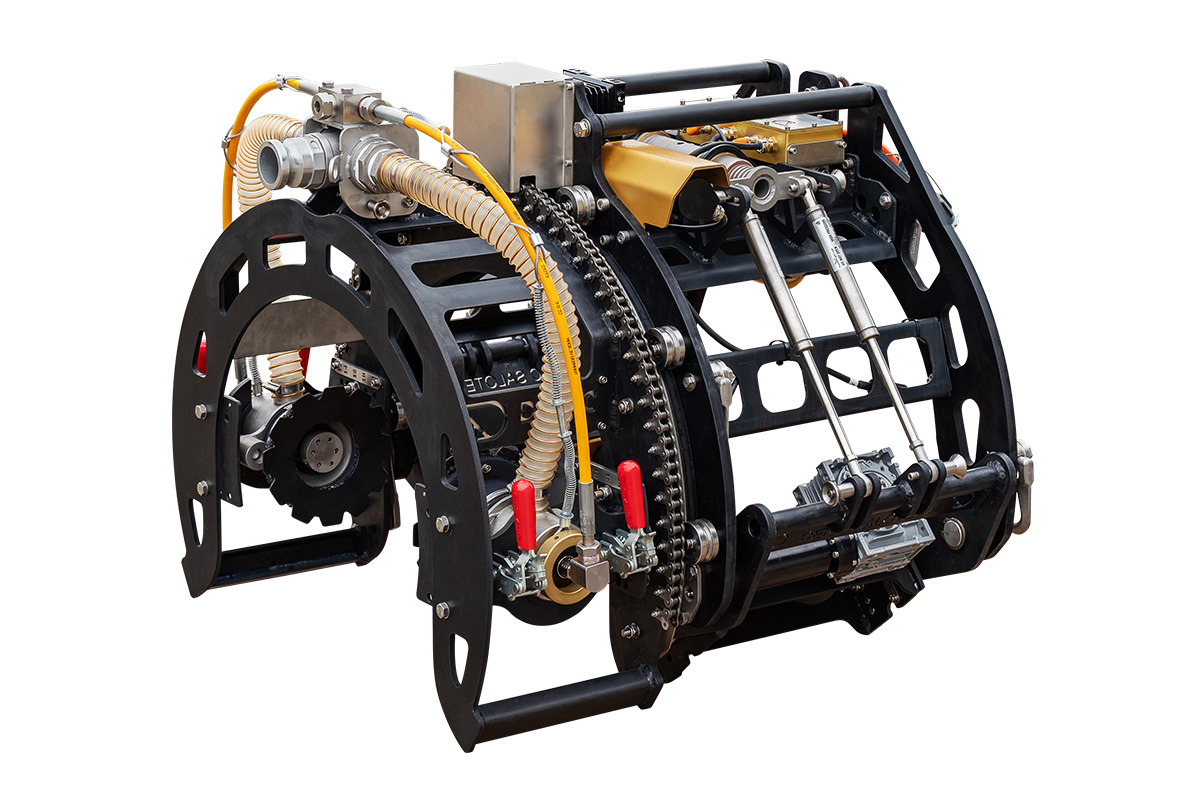

DiscoverDERC Flexa-Jet Abrasive Cutting System

Versatile system for industrial cold cutting applications using ultra-high pressure water.

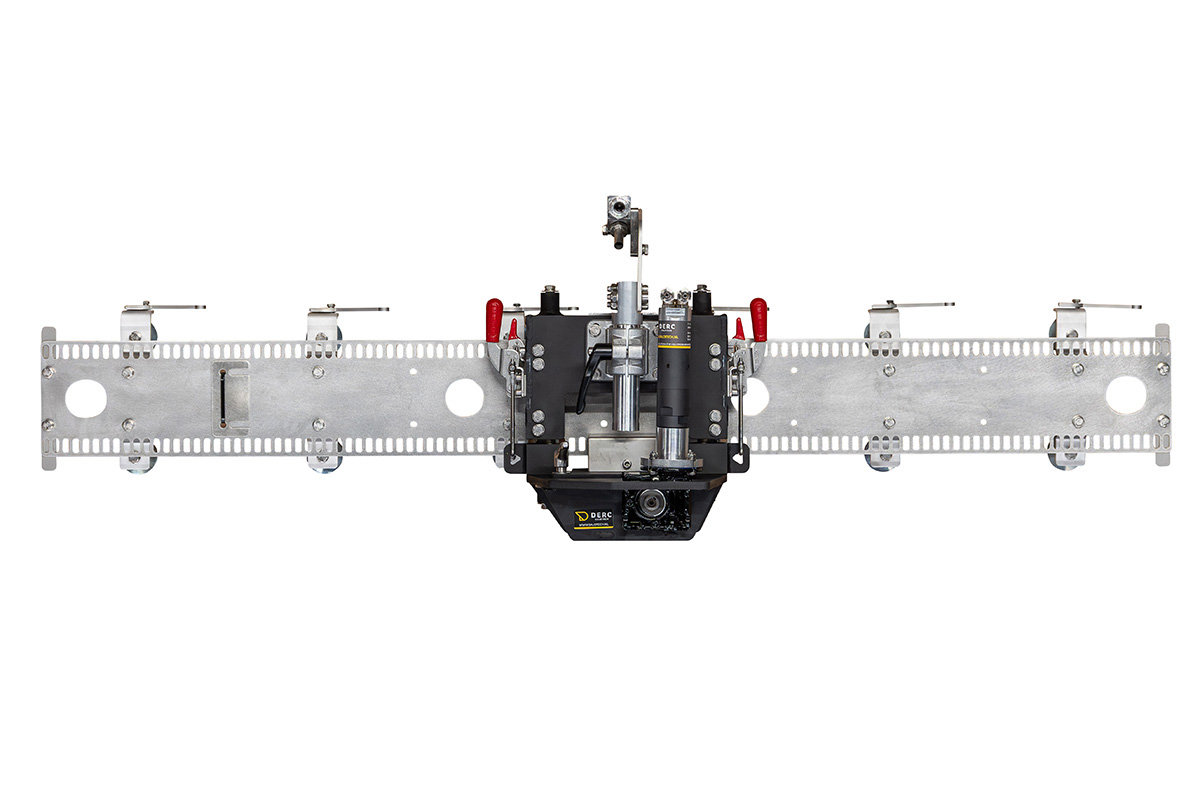

DiscoverDERC MagTrack

Modular magnetic robotic crawler for UHP industrial cleaning and surface preparation jobs.

DiscoverRisk assessment for high pressure water jetting is a systematic process of identifying, evaluating, and controlling potential hazards before starting any water jetting work. This involves examining the work environment, equipment, and procedures to determine what could cause harm to operators or bystanders. A proper risk assessment helps prevent serious injuries, ensures compliance with safety regulations, and creates safer working conditions for everyone involved in industrial cleaning operations.

Understanding risk assessment in high pressure water jetting operations

Risk assessment in high pressure water jetting means taking a careful look at your work environment and equipment to identify what could potentially go wrong. It’s about being proactive rather than reactive, helping you spot dangers before they become accidents. This systematic approach is particularly important in industrial cleaning operations where water pressures can exceed 40,000 PSI (2,758 BAR).

The importance of proper risk assessment cannot be overstated when you’re working with equipment that can cut through steel. High pressure water jetting poses unique hazards that require careful evaluation and planning. By conducting thorough assessments, you protect not only your operators but also nearby workers and equipment from potential harm.

Risk assessment is defined as a systematic process that involves identifying hazards, evaluating the likelihood and severity of potential incidents, and implementing appropriate control measures. This process must be documented and communicated to all team members before any water jetting work begins. It’s not just good practice, it’s a fundamental requirement for safe operations.

Various regulatory requirements and industry standards mandate proper risk assessment procedures. These include local health and safety regulations, industry-specific guidelines, and international standards that outline minimum safety requirements for high pressure water jetting operations. Compliance with these standards helps ensure consistent safety practices across different work sites and projects.

What are the main hazards in high pressure water jetting?

The primary hazards in high pressure water jetting operations are numerous and potentially severe. Direct contact with the water jet can cause immediate and catastrophic injuries, including deep lacerations, amputations, and even fatalities. Injection injuries occur when high-pressure water penetrates the skin, potentially causing serious internal damage that may not be immediately visible.

Flying debris presents another significant risk during water jetting operations. As the high-pressure stream removes material from surfaces, particles can become projectiles traveling at dangerous speeds. Slip and fall risks from wet surfaces are constant concerns, especially in industrial environments where proper drainage may be limited. Additionally, noise exposure from equipment operation can exceed safe levels, potentially causing permanent hearing damage without proper protection.

Secondary hazards add another layer of complexity to risk assessment. When cleaning contaminated surfaces, operators may face chemical exposure risks from dissolved or aerosolized substances. Confined space operations introduce dangers such as limited escape routes and potential atmospheric hazards. Electrical hazards become particularly concerning when water operations occur near powered equipment or electrical installations.

The severity of these hazards varies significantly based on operational parameters. Higher pressure levels increase the potential for severe injuries, while water temperature affects both injury severity and the risk of steam-related burns. Different nozzle types and configurations can create varying hazard profiles, from focused cutting jets to wider fan patterns that may generate more aerosol and debris.

How do you conduct a proper risk assessment for water jetting?

Conducting a proper risk assessment starts with a comprehensive job site evaluation and thorough equipment inspection. Walk through the entire work area, examining surfaces to be cleaned, identifying obstacles, and noting any environmental factors that could affect safety. Check all equipment components, including hoses, fittings, nozzles, and safety devices, ensuring everything meets operational standards.

Identifying specific hazards requires careful consideration of each work area and task. Look for potential strike zones where the water jet could contact workers, evaluate surface conditions that might create slip hazards, and identify any confined spaces or areas with limited visibility. Consider how the work might affect or be affected by other operations happening nearby.

The risk matrix methodology provides a structured approach to evaluate hazards. For each identified hazard, assess both the likelihood of occurrence and the potential severity of consequences. This creates a risk rating that helps prioritize which hazards require the most immediate attention. Document these findings clearly, using standardized forms that capture all relevant information.

Determining control measures and establishing safe work procedures comes next. Based on your risk ratings, develop specific strategies to eliminate or reduce each hazard. Create detailed standard operating procedures that outline step-by-step safety requirements. Remember to involve operators and supervisors throughout this process, as their practical experience provides invaluable insights into real-world challenges and effective solutions.

What safety controls should be implemented based on risk assessment?

The hierarchy of controls provides a framework for implementing safety measures, starting with elimination and substitution where possible. If you can remove the hazard entirely or replace it with something less dangerous, that’s always the preferred option. For example, using automated systems instead of manual operation eliminates direct operator exposure to certain hazards.

Engineering controls form the next line of defense. These include pressure relief devices that prevent equipment over-pressurization, dead man switches that stop operation if the operator loses control, and protective barriers that shield workers from water jets and debris. Physical guards, interlocks, and automated shut-off systems all fall into this category of built-in safety features.

Administrative controls encompass the policies and procedures that govern safe work practices. This includes comprehensive training requirements ensuring all operators understand equipment operation and safety protocols. Permit systems help control access to hazardous areas and ensure proper safety measures are in place. Standard operating procedures provide consistent guidance for routine tasks and emergency situations.

Personal protective equipment specifications must match the specific hazards identified in your risk assessment. Specialized suits rated for high pressure water exposure, full face shields with appropriate impact ratings, and safety boots designed to withstand water jet contact are essential. Don’t forget about hearing protection, as prolonged exposure to equipment noise can cause permanent damage. Emergency response planning should address water jetting-specific injuries, including protocols for injection injuries that require immediate medical attention.

Why is regular review of risk assessments important?

Workplace conditions are dynamic, constantly changing as projects progress, equipment ages, and new challenges arise. What was safe yesterday might not be safe today if conditions have changed. Regular reviews ensure your risk assessments remain relevant and effective in protecting workers from current hazards.

Several triggers should prompt immediate risk assessment reviews. Equipment changes, whether replacing components or introducing new machinery, can alter the hazard profile significantly. Any incident or near-miss provides valuable learning opportunities that should be incorporated into updated assessments. New regulations or changes in work scope also necessitate fresh evaluation of risks and controls.

Continuous improvement through lessons learned and near-miss reporting creates a culture of safety awareness. When operators feel comfortable reporting close calls without fear of punishment, you gain insights into potential failures before they cause injuries. This proactive approach helps identify gaps in current safety measures and opportunities for enhancement.

Updating assessments based on operator feedback ensures practical, workable solutions. The people using equipment daily often have the best understanding of real-world challenges and effective workarounds. Technological advances in safety equipment also provide opportunities to improve protection levels, making regular reviews essential for incorporating the latest safety innovations.

How DERC Salotech supports safe water jetting operations

We understand that safety is paramount in high pressure water jetting operations, which is why we’ve built safety features directly into our equipment design. Our innovative systems incorporate multiple safety mechanisms that work together to protect operators while maintaining operational efficiency. From pressure relief valves to automated shut-off systems, every component is engineered with operator safety in mind.

Through DERC Adviesgroep, we offer certified training courses that cover comprehensive risk assessment procedures and safe operating practices. These courses combine theoretical knowledge with hands-on experience, ensuring operators understand both the why and how of safety protocols. Our training programs are developed based on real-world experience and continuously updated to reflect the latest safety standards and best practices.

Our flagship products, including the Flexa-Jet Chain Manipulator and MagTrack robotic system, exemplify our commitment to minimizing operator exposure to hazards. These systems allow remote operation of high-pressure water jets, keeping operators at safe distances from the most dangerous zones. The built-in safety features include emergency stops, pressure monitoring, and fail-safe mechanisms that activate automatically if problems arise.

For personal protection equipment PPE we cooperate with TST-Sweden. They supply a complete line of PPE equipment for high pressure water jetting up to 3000 Bar / 43.000 PSI

With our global presence in over 55 countries, we’ve helped establish best practices for risk assessment across diverse industries and regulatory environments. This international experience allows us to share insights and solutions that have proven effective in various challenging conditions. Whether you’re working in petrochemical facilities, marine environments, or general industrial settings, our equipment and expertise support your safety goals. Explore our complete range of safety-enhanced equipment options on our products page to find solutions tailored to your specific risk assessment requirements.

Questions?

Get in touch with our support team

+31 186 - 62 14 84