Product

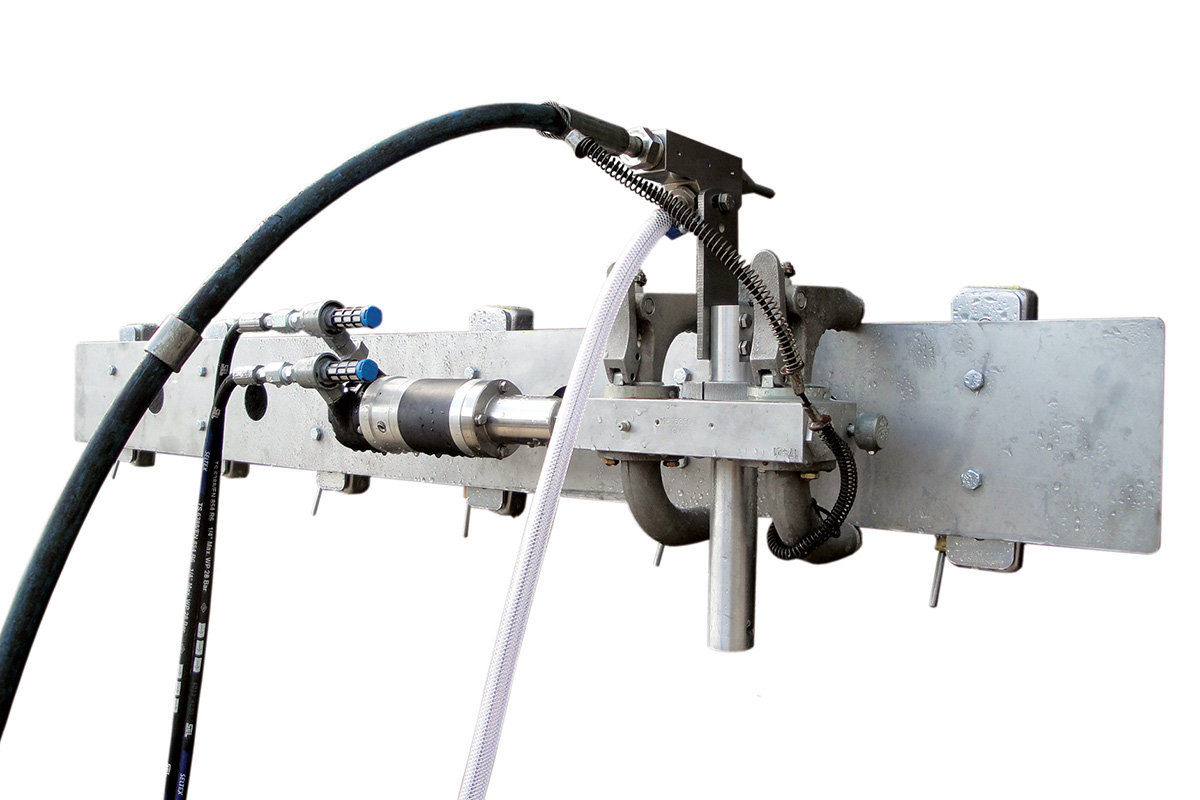

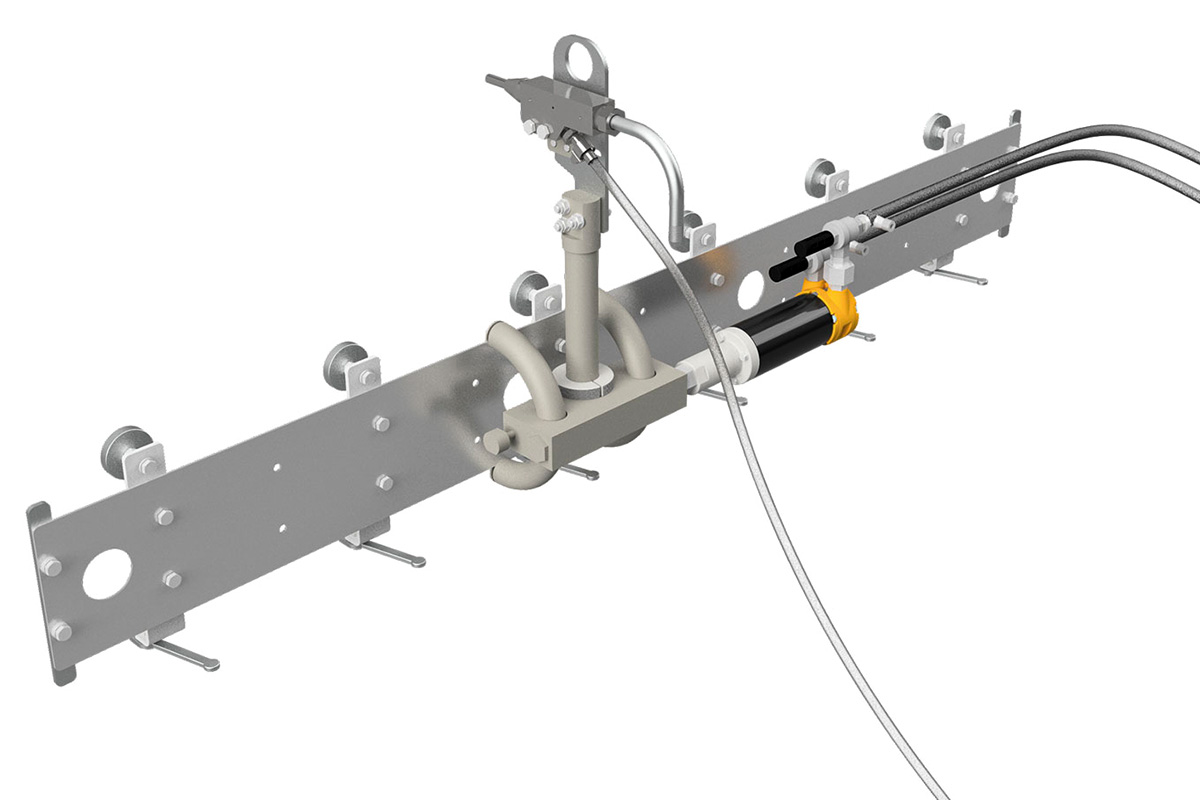

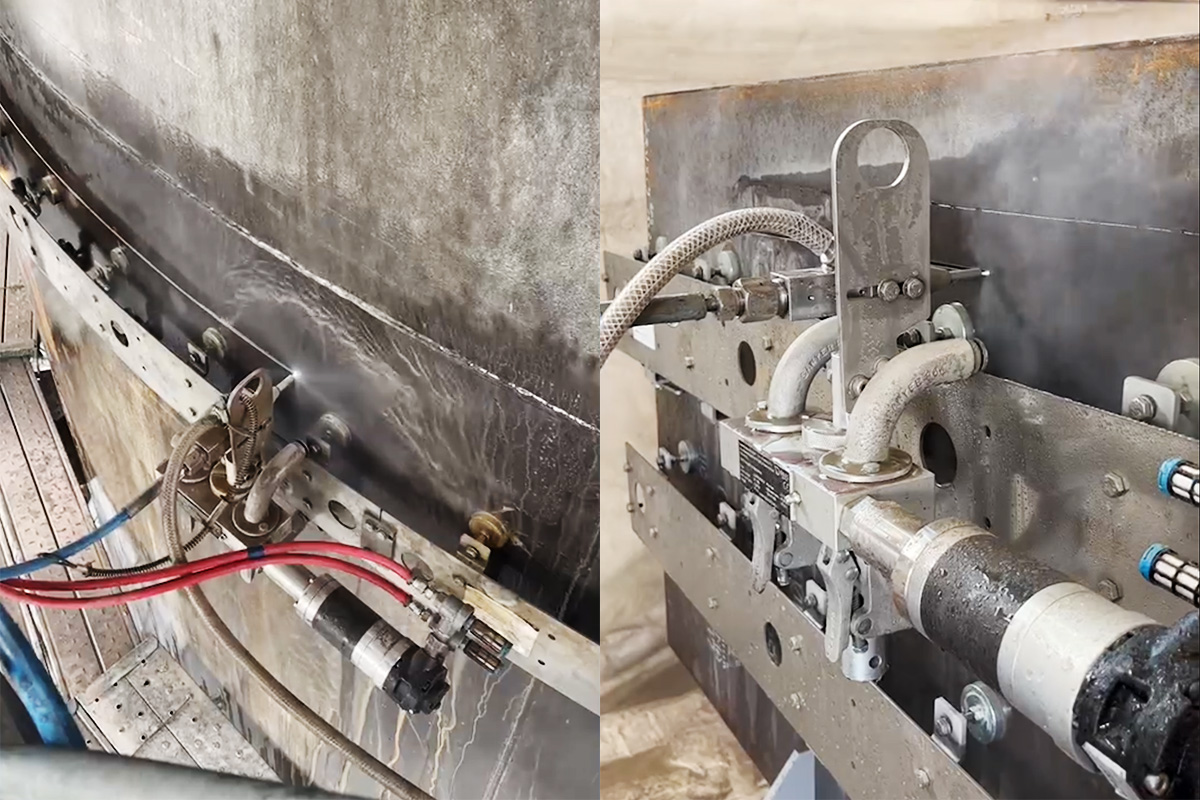

DERC Abrasive Cutting System

Your Solution For Cutting Metal Safely

The DERC Abrasive Water Jet Cutting System is designed and manufactured for industrial cold cutting applications with ultra-high pressure water. The system consist of a cold cutting head which is moved over a track (magnetic or optional vacuum) by means of the so called power head. The power head is driven by an air engine and is able to move over the track (straight or curved objects). The same power head drives over the so called pipe bands used for pipe cutting as well. See the range of optional pipe bands in the table below.

Hopper & Abrasive Monitoring System

The abrasive which runs to the cold cutting head is stored into the hopper. This hopper is dolly mounted for easy transportation on the job site. The abrasive feed rate is controlled by the abrasive monitoring device ensuring a constant well adjustable flow of abrasive.

Control Panel

The cold cutting head is fixed to the power head and can be positioned parallel or perpendicular to the track. Control of movement, speed and abrasive is done from the control panel which comes with the cutting system.

Basic System

+ Powerhead

+ Cutting Nozzle

+ Magnetic Flex Track

+ Hopper with abrasive monitoring system

+ Control panel

Custom Made Solutions

For more special jobs DERC Salotech is able to deliver a wide range of options and custom made solutions like:

+ Pipe bands for cutting pipes

+ Manhole Cutter

+ Cutting window for special shapes or objects

+ Radius Cutter for small diameters and or radius cutting

+ Internal Pipe Cutter

The Flexible Magnetic Track and the Manhole Cutter can be supplied with permanent magnets or releasable magnets.

BASIC CUTTING SET

PART NO.

DESCRIPTION

D.MAGTRACK.AS

Flexible Magnetic Track 1,5 meter, made from stainless steel spring steel with permanent magnets

D.MAGTRACK.AS-1500-RMAG

Flexible Magnetic Track 1,5 meter, made from stainless steel spring steel with releasable magnets

D.DRIVEHEAD.A-VS

Power head complete (air), delivered complete with cutting head holder to cut parallel and perpendicular

D.ABHOPPER.AS

Hopper assy. stainless steel trolley, complete with abrasive monitoring system and abrasive transport hose

CPA-AWCS

Control panel for abrasive cutting system, complete with 3 hoses

D.ABCUTTIN.AS

Cutting Nozzle Assembly complete 3000 Bar

OPTIONAL PIPE BANDS

PART NO.

DESCRIPTION

D.PBAND.8

Pipe band 8”

D.PBAND.10

Pipe band 10”

D.PBAND.12

Pipe band 12”

D.PBAND.14

Pipe band 14”

D.PBAND.16

Pipe band 16”

D.PBAND.18

Pipe band 18”

D.PBAND.20

Pipe band 20”

D.PBAND.24

Pipe band 24”

* Other diameters are available on request

OPTIONAL ACCESSORIES

PART NO.

DESCRIPTION

D.ABCUTTIN.03

Spare cone TC for cutting nozzle

D.ABCUTTIN.10

Spare slurry nozzle TC for cutting nozzle

965.xxx

HP Nozzle M10 model 965

Support

Our expert staff are available Monday to Friday from 8:00 AM - 4:30 PM (CET) to answer all your questions about this product.

Support

Our expert staff are available Monday to Friday from 8:00 AM - 4:30 PM (CET) to answer all your questions about this product.