Product

DERC Flexa-Jet Abrasive Cutting System

Your Ultimate Flexible Solution for Water Jet Abrasive Cutting

The Flexa-Jet Cutting System is designed for industrial cold cutting using ultra-high pressure water. This innovative system combines simplicity, accuracy, and versatility.

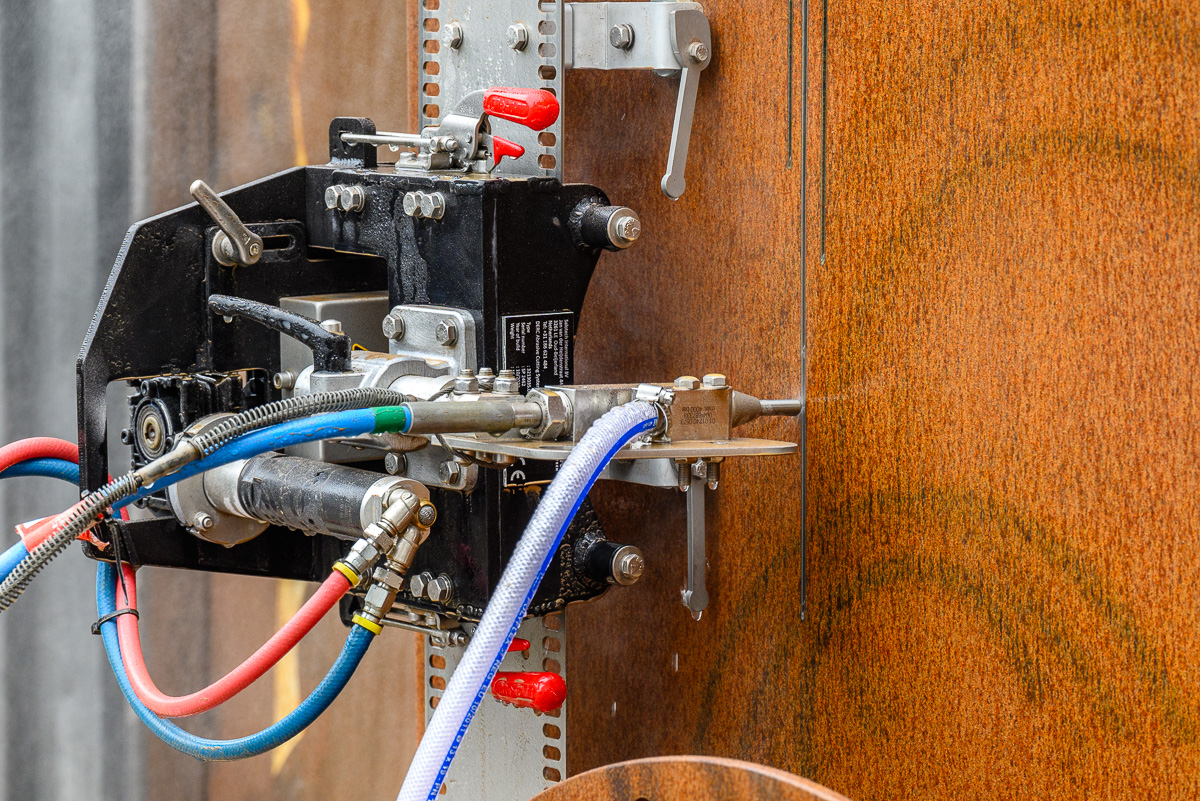

Flexa-Jet Tractor:

This air-powered drive unit propels the cutting head along the Flexa-Jet Track and Pipe Bands. Due to it’s direct drive onto the track and pipeband, it ensures continuous movement, with a standard gear that is easy to change for different speeds/ratios.

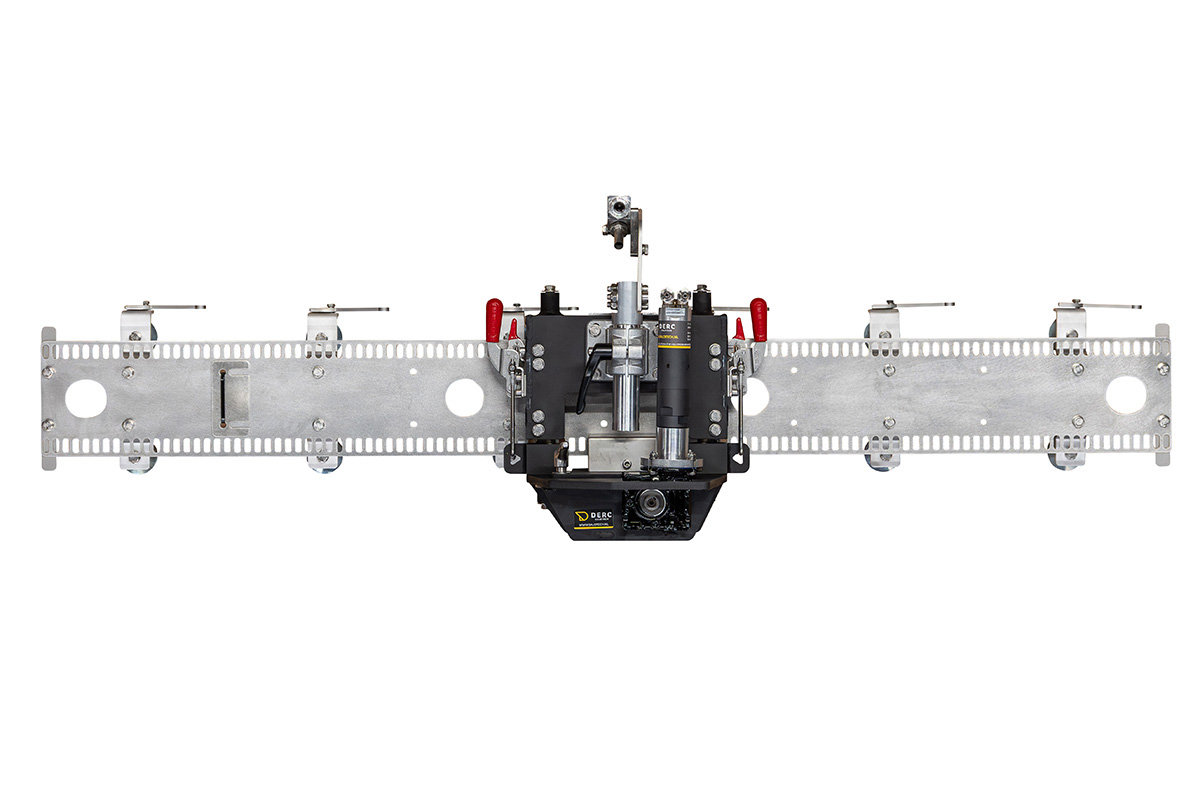

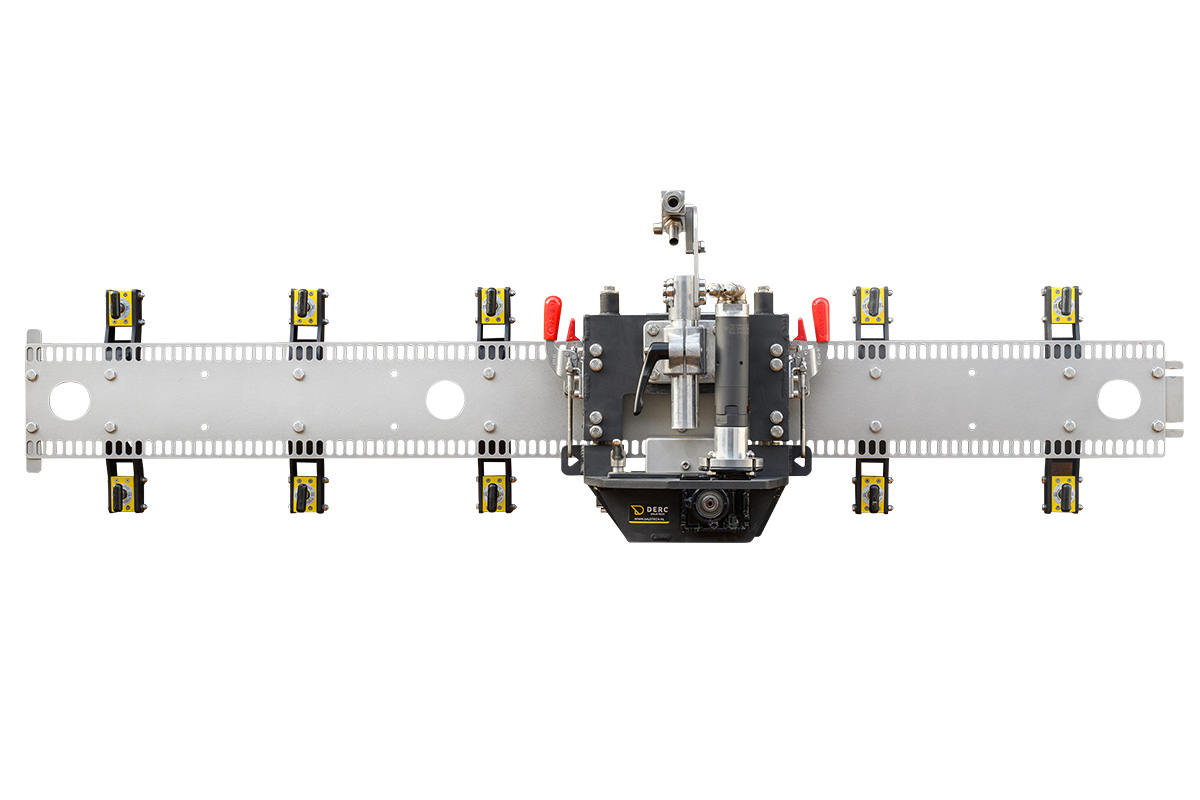

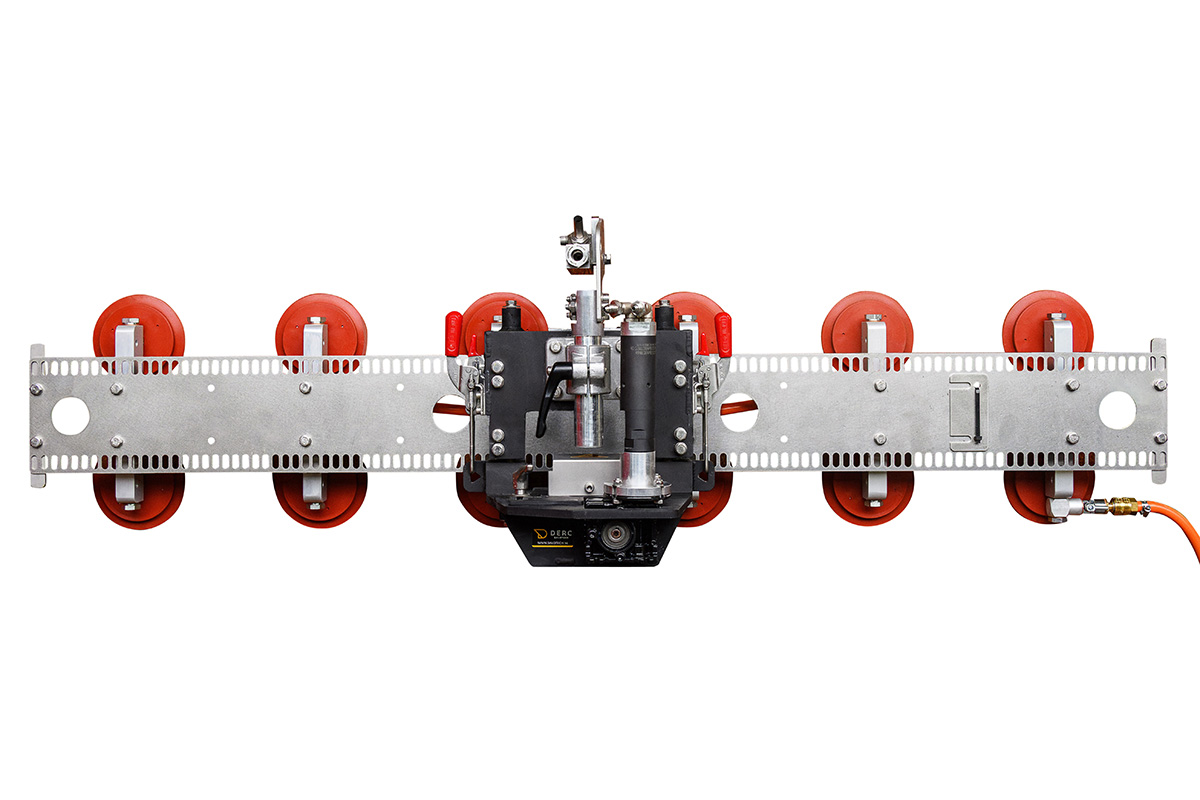

Flexa-Jet Track:

This flexible track system can be mounted with fixed or releasable magnets, or a vacuum attachment, providing secure and adaptable mounting options. It ensures smooth movement of the Flexa-Jet Tractor for precise and consistent cuts.

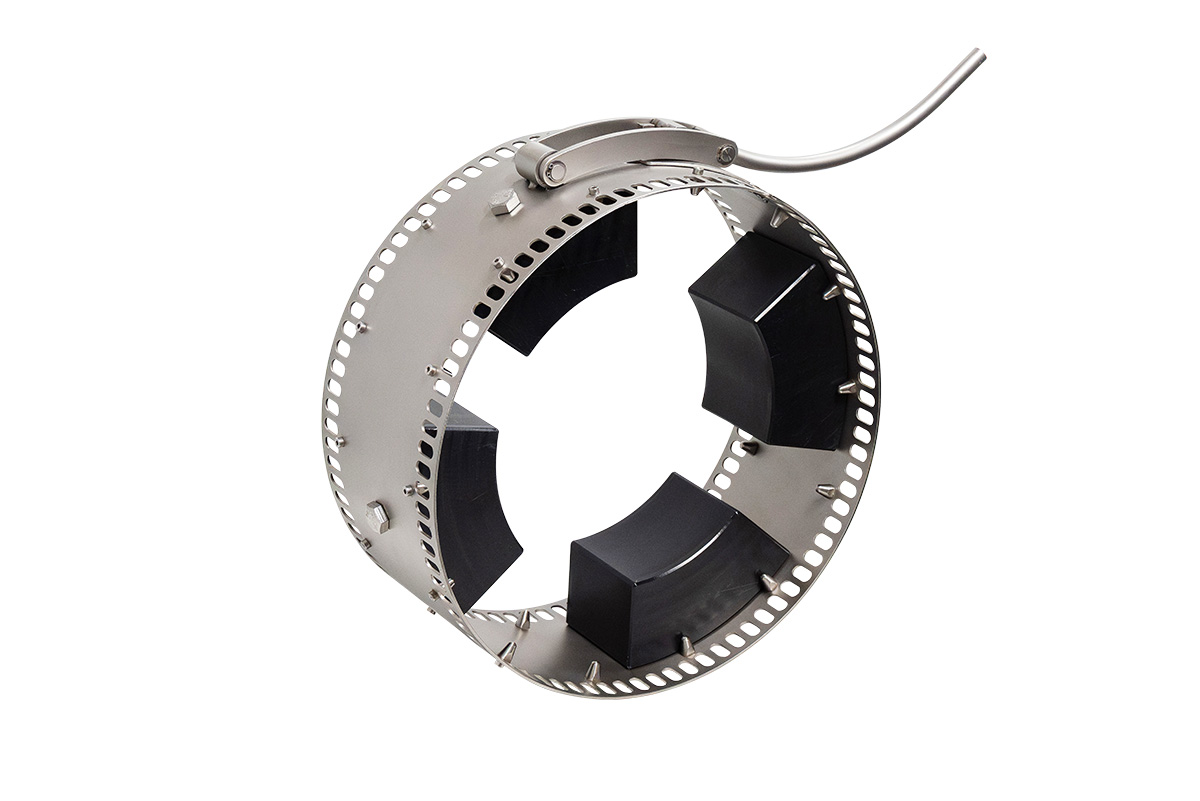

Flexa-Jet Pipe Bands:

These curved tracks wrap around pipes for precise pipe cutting. One Flexa-Jet Pipe Band with reducer blocks is used for 6”–10” pipes, while separate pipe bands are available for 12”–24” pipes. The Flexa-Jet Tractor navigates these bands efficiently across various pipe diameters.

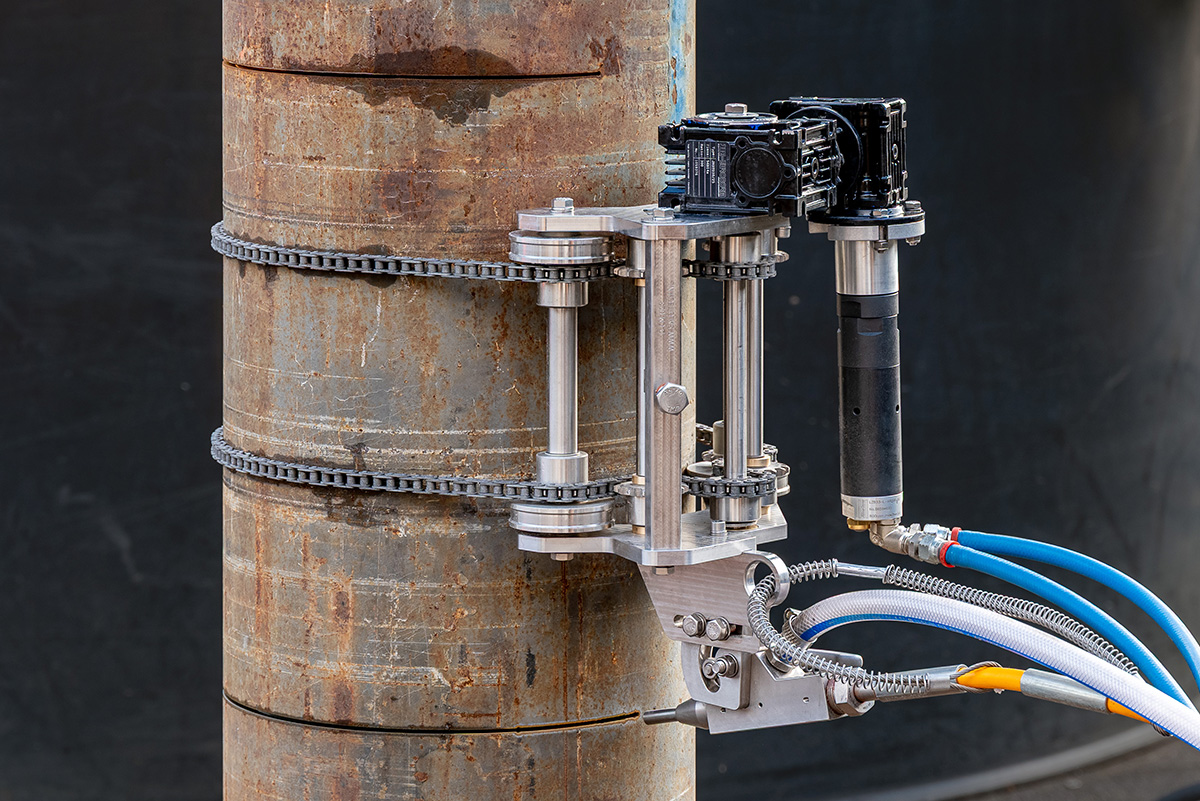

Flexa-Jet Chain Manipulator

A precision tool developed for abrasive waterjet cutting of pipes with a minimum diameter of 6” (ø168 mm). It is more compact and diameter flexible in regards to adjustments than the Pipe Bands.

Cold Cutting Head:

Fixed to the Flexa-Jet Tractor, it can be positioned for parallel or perpendicular cuts to the Flexa-Jet Track, providing flexibility for straight and curved cuts.

Flexa-Jet Hopper & Abrasive Monitoring System:

The mobile hopper stores the abrasive and allows easy transport around the job site. The monitoring device regulates the feed rate for consistent and adjustable flow to the cutting head, optimizing efficiency.

Flexa-Jet Control Panel:

This panel offers complete control over the cutting process, including movement, speed, and abrasive flow, ensuring precise operation and safety. For the vacuum cup track, a vacuum generator is installed on the control panel.

Basic System Configuration

- Flexa-Jet Tractor

- Flexa-Jet Track (mountable with fixed or releasable magnets, or vacuum)

- Cold cutting head with cutting nozzle

- Hopper with abrasive monitoring system

- Control panel

BASIC CUTTING SET

PART NO.

DESCRIPTION

D.CUT.TRACK.PM

Flexa-Jet Track direct drive - 1,5 m stainless steel spring steel with permanent magnets

D.CUT.TRACK.SM

Flexa-Jet Track direct drive - 1,5 m stainless steel spring steel with switchable magnets

D.CUT.TRACK.VP

Flexa-Jet Track direct drive - 1,5m stainless steel spring steel with vacuum pads

D.CUT.POWERHEAD

Flexa-Jet Tractor direct drive complete (air), delivered complete with cutting head holder to cut parallel and perpendicular

D.ABHOPPER.AS-B

Hopper assembly stainless steel trolley, complete with abrasive monitoring system and abrasive transport hose

CPA-AWCS

Control panel for abrasive cutting system, complete with 3 hoses

CPA-AWCS-VAC

Control panel for abrasive cutting system, complete with 3 hoses, for vacuum pads

D.ABCUTTIN.AS

Cutting nozzle assembly complete 3000 Bar

OPTIONAL PIPE BANDS

PART NO.

DESCRIPTION

D.PB.12

Pipe band 12” direct drive

D.PB.14

Pipe band 14” direct drive

D.PB.16

Pipe band 16” direct drive

D.PB.18

Pipe band 18” direct drive

D.PB.20

Pipe band 20” direct drive

D.PB.24

Pipe band 24” direct drive

D.PB-RB-6

Reducer block set for reducing 12” pipe band to 6”

D.PB.RB-8

Reducer block set for reducing 12” pipe band to 8”

D.PB.RB-10

Reducer block set for reducing 12” pipe band to 10”

* Other diameters are available on request

OPTIONAL ACCESSORIES

PART NO.

DESCRIPTION

D.ABCUTTIN.03

Spare cone TC for cutting nozzle

D.ABCUTTIN.10

Spare slurry nozzle TC for cutting nozzle 2,5mm

D.ABCUTTIN.10.20

Spare slurry nozzle TC for cutting nozzle 2,0mm

D.ABCUTTIN.10.30

Spare slurry nozzle TC for cutting nozzle 3,0mm

HP nozzle M10 model 965

Support

Our expert staff are available Monday to Friday from 8:00 AM - 4:30 PM (CET) to answer all your questions about this product.

Support

Our expert staff are available Monday to Friday from 8:00 AM - 4:30 PM (CET) to answer all your questions about this product.