Stay Informed

Resource center

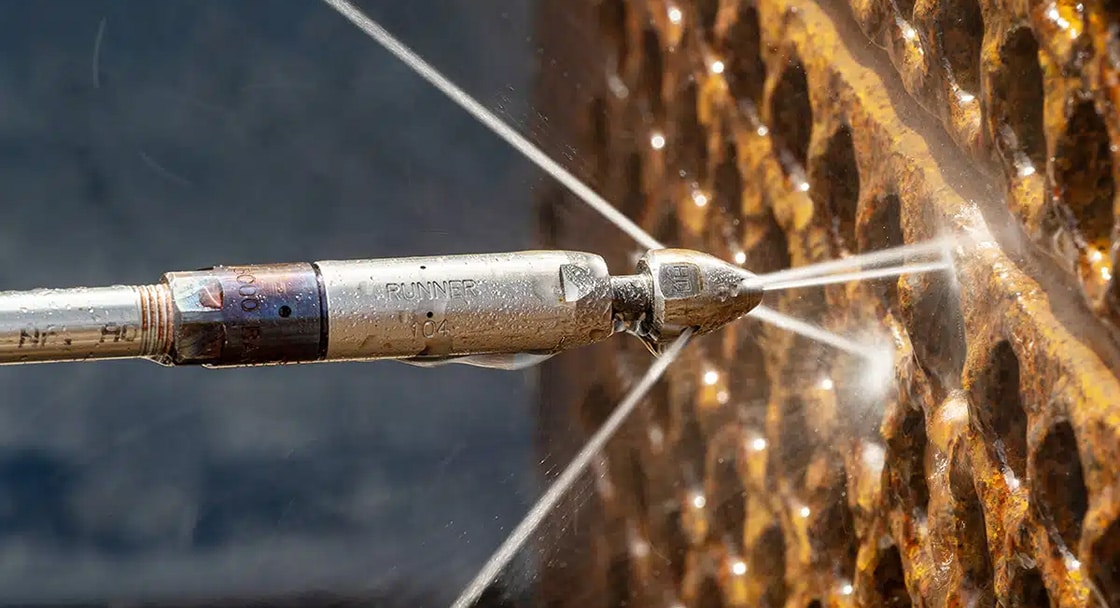

What tube cleaning methods work best for scale removal?

High-pressure water jetting stands out as the most effective tube cleaning method for scale removal in industrial applications. This mechanical cleaning technique uses water pressures ranging from 500 to 3000 bar (7,250 to 43,500 psi)...

Read moreWhat is the risk assessment for high pressure water jetting?

Risk assessment for high pressure water jetting is a systematic process of identifying, evaluating, and controlling potential hazards before starting any water jetting work. This involves examining the work environment, equipment, and procedures to determine...

Read moreAt what pressure does water cut steel?

Water needs extremely high pressure to cut through steel, typically ranging from 30,000 to 90,000 PSI (2,068 to 6,205 BAR) (pounds per square inch). However, water pressure alone isn't enough for effective steel cutting. Most...

Read moreWhat are the OSHA requirements for high pressure washers?

While OSHA doesn't have specific regulations exclusively for pressure washers, operators must comply with various safety standards including the General Duty Clause, 29 CFR 1910.95 for noise exposure, and general PPE requirements. These regulations mandate...

Read moreHow do I increase water jet pressure?

To increase water jet pressure, you need to focus on three main areas: optimising your pump settings, selecting the right nozzle size, and maintaining your equipment properly. Start by checking your pressure regulator and unloader...

Read moreHow much pressure do you need for a sewer jetter?

For effective sewer jetting, you need pressure ranging from 1,500 to 4,000 PSI (103 to 276 BAR) depending on your specific application. Residential systems typically require 1,500-2,500 PSI (103-172 BAR), whilst industrial applications often need...

Read moreWhat are the risks of high pressure water jetting?

High pressure water jetting carries significant risks including severe injection injuries, equipment failures and environmental hazards. The extreme pressures involved can cause deep tissue damage, cuts and impact trauma. Equipment malfunctions such as hose ruptures...

Read moreHow does high pressure water nozzle work?

High pressure water nozzles work by forcing water through a precisely designed orifice at extreme pressure, converting that pressure into high-velocity water jets that can remove stubborn contaminants, coatings, and debris from industrial surfaces. The...

Read more