Product

DERC Rigid Lance Cleaning System RLC

Safe and Fast Cleaning of Heat Exchanger Tubes

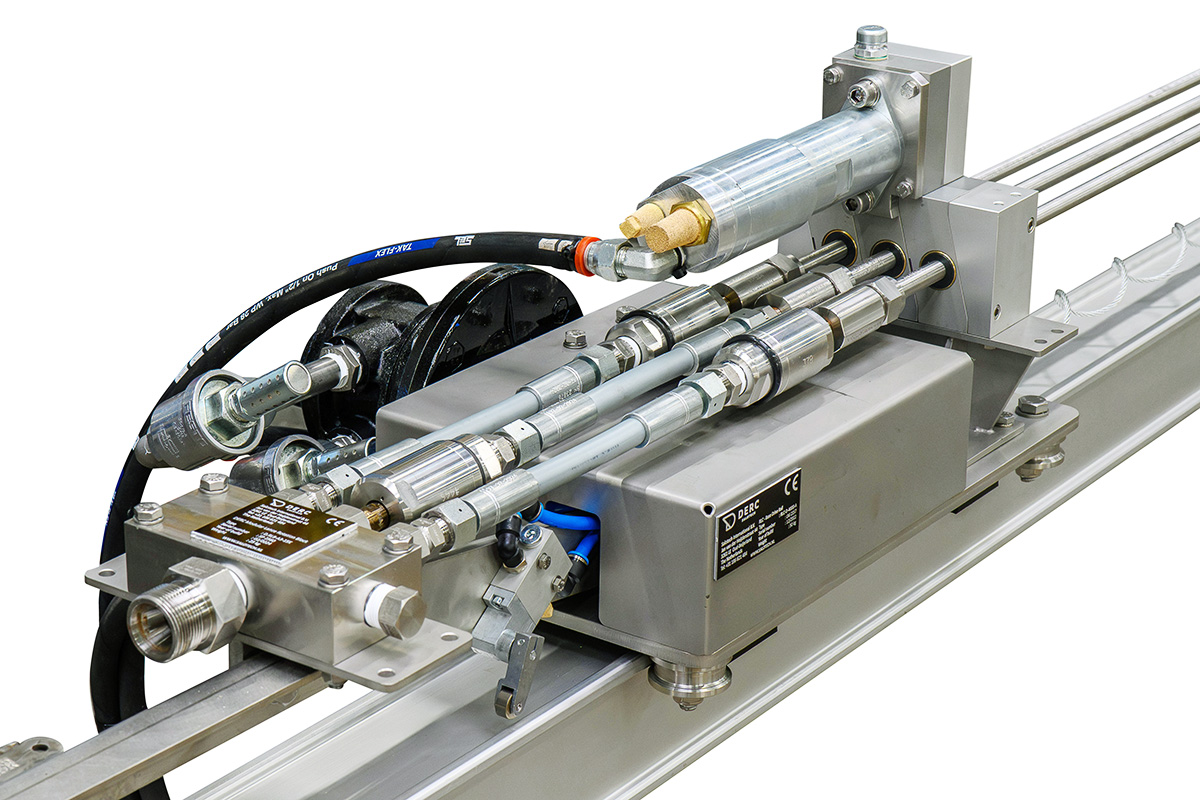

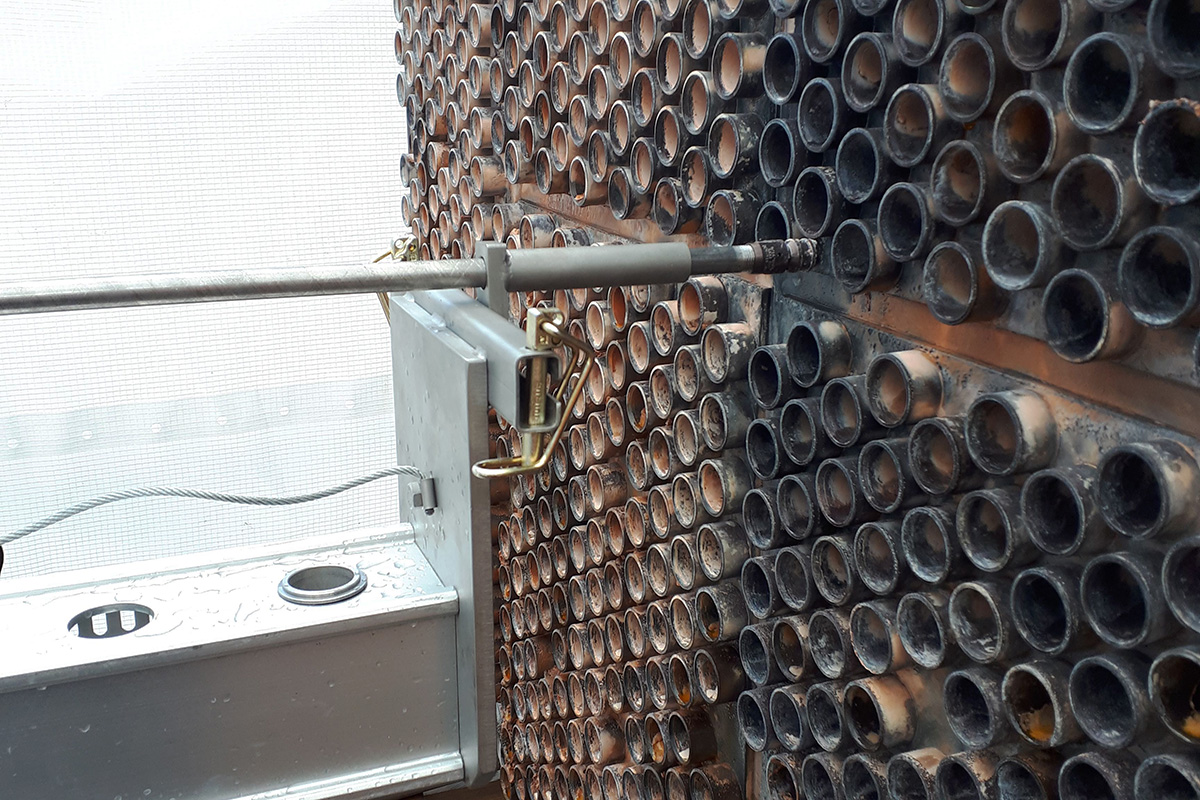

The DERC Rigid Lance Cleaning System is a modular rigid lancing system to clean heat exchanger tube bundles. It is perfect for safe and fast removal of hard plugs, scaling and general cleaning of heat exchangers. The RLC is easy to adapt to any length and suitable for a maximum working pressure of 3000 bar.

X-Y Positioner

For positioning the lances in front of the heat exchanger the RLC system comes with an X-Y Positioner. This X-Y Positioner can be used for horizontal or vertical applications of the RLC. For horizontal aplications it consists of a removable wheel kit, support stands / legs and scaffolding guides. For vertical applications the X-Y positioner is mounted to the tube bundle.

Rear Support / A-Frame

For stability the RLC is equipped with a rear support. For horizontal applications this is an A-Frame with a movable support chain. For vertical applications a custom solution is needed depending on the length of the aluminum rail.

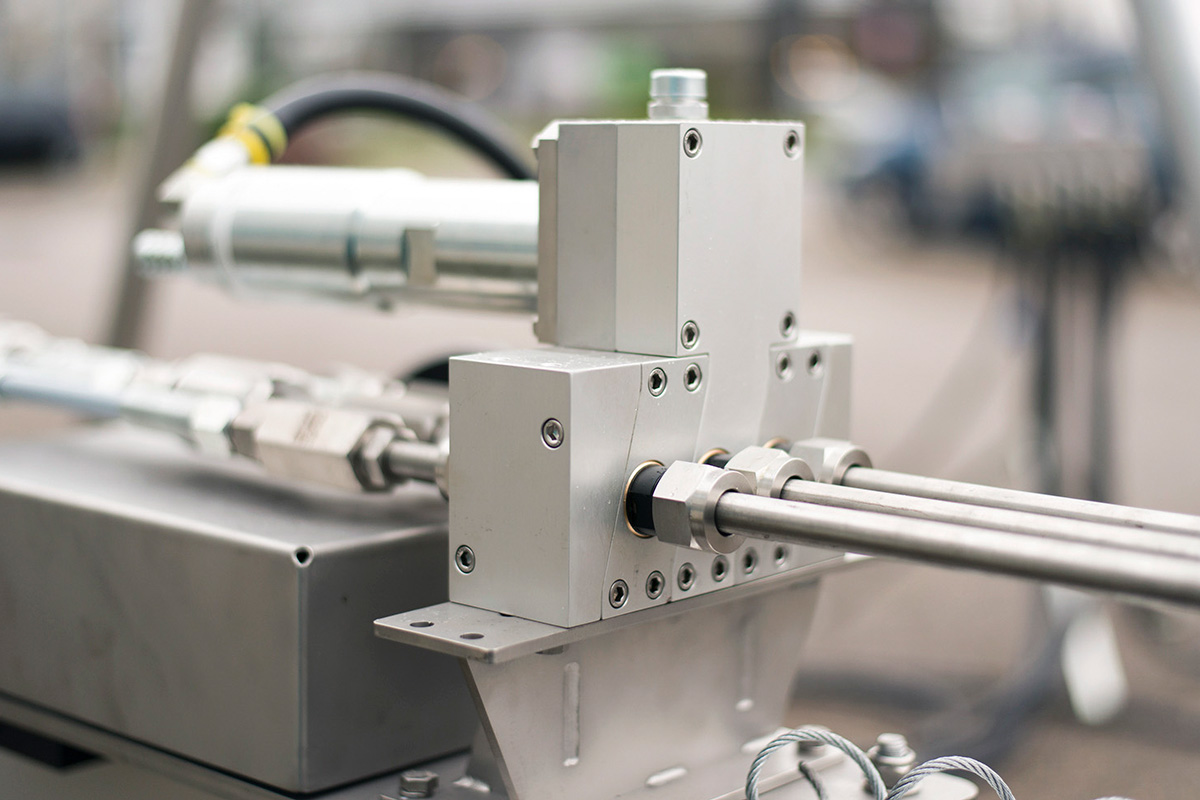

Modular Lance Rotation Drive Unit

On the lance carriage you will find our Modular Lance Rotation Drive Unit. This modular block can be converted to rotate 1, 2, 3 or 5 high pressure lances in any pressure range.

Automated Solutions Rail

The basis of the RLC system is an aluminum rail with gear rack on which a modular rotating lancing carriage drives the lances in and out the heat exchanger tubes.

Operation at a Safe Distance

For controlling all the functions of the RLC system the machine comes with an operating panel, placing the operator out of the line of fire.

Power

The RLC system is standard fully air powered, however on request we can offer a hydraulic version of the system.

Nozzles and Lances

Based on your requirements, DERC Salotech offers a full range of nozzle and lance configurations for the RLC.

DERC Tube Bundle Roller (Optional)

The DERC Tube Bundle Rollers are heavy duty rollers for any bundle up to 25,000 kg. These rollers rotate pipe bundles during cleaning. The DERC Tube Bundle Rollers come as a set of 2. Each set has 4 rollers, to ensure a good support of the bundle. On one of the two sets the 4 rollers are driven. The rollers on the other set follow (no drive). The drive engine can be driven either pneumatic or hydraulic.

DERC Shell Side Blaster SSB (Optional)

The SSB is an automated solution for external cleaning of heat exchangers with high pressure water jets. The SSB makes tube bundle blasting of shell side cleaning simple and safe, placing the operator at a safe distance out of the line of fire! The SSB consists of two wheeled frames, which can be placed over the heat exchanger, and adjusted in height by means of two manually operated hand wheels. The system comes with two tensioner chains to secure the frames to your tube bundle rollers.

Support

Our expert staff are available Monday to Friday from 8:00 AM - 4:30 PM (CET) to answer all your questions about this product.

Support

Our expert staff are available Monday to Friday from 8:00 AM - 4:30 PM (CET) to answer all your questions about this product.